Industries We Serve in North Las Vegas

Frequency X Electric supports a wide range of industrial environments throughout North Las Vegas and surrounding regions. Our team brings extensive field experience across mining operations, concrete production, aggregate processing, manufacturing facilities, thermosolar installations, and project management–driven environments. These industries depend on electrical systems that operate with precision, consistency, and resilience under demanding conditions. The work performed in these environments requires specialized knowledge of electrical controls, automation, high-performance distribution, and performance-based infrastructure. Frequency X Electric

provides that expertise through comprehensive service, installation, troubleshooting, and ongoing support.

Electrical and Maintenance Support for Open Pit Mines and Gravel Pits

Mining operations rely heavily on robust electrical systems capable of supporting continuous production and high electrical loads. Open pit mines and gravel pits in the North Las Vegas region frequently operate MCCs, VFD-controlled motors, automated control networks, and process instrumentation. Frequency X Electric

provides service and maintenance solutions tailored specifically for these environments, where downtime impacts production output and system safety is essential.

Mining System Requirements

Mining operations demand stable electrical infrastructure capable of managing variable loads, high-vibration conditions, and abrasive environmental factors. Electrical components must function reliably under prolonged exposure to dust, heat, and continuous-duty cycles. Our team evaluates and maintains control systems, drive components, PLC networks, and instrumentation to support consistent operation. Mining sites often require rapid troubleshooting response, electrical system optimization, and automation reliability management. Frequency X Electric provides these services with the technical depth required for mining applications.

Concrete Batch Plant Equipment Services and Electrical Support

Concrete batch plants operate complex systems that coordinate electrical controls, batching instrumentation, load measurement devices, and automated processes. These plants depend on precise electrical system performance to

maintain mix accuracy, timing reliability, and operational safety. Frequency X Electric supports concrete batch plants with installation, diagnostics, and maintenance services that ensure electrical infrastructure functions correctly

throughout production cycles.

Batch Plant Electrical Demands

Batching systems require accuracy, and electrical components must communicate seamlessly to maintain consistency in production. Instrumentation, PLC controls, motor starters, and drive systems must synchronize during each stage. Frequency X Electric

evaluates system timing, control logic, instrumentation calibration, and equipment wiring to ensure consistent performance under heavy industrial demand.

Aggregate Processing Facilities and Plant-Wide Electrical Systems

Aggregate processing involves screening, crushing, washing, and material separation, all of which rely on well-coordinated electrical and control systems. Frequency X Electric provides services that ensure aggregate facilities

maintain reliable control, energy efficiency, and operational stability. These environments require comprehensive knowledge of automated controls, motor coordination, sequencing logic, sensors, instrumentation, and plant-wide

electrical distribution.

Electrical Integration in Aggregate Environments

Aggregate plants depend on well-integrated systems that manage sequence starts, auxiliary equipment, safety stops, and automated load adjustments. We assess and maintain MCCs, PLC-based systems, motor controls, sensors, and instrumentation to ensure plants operate efficiently under heavy production demand. Electrical evaluations include system condition assessments, performance benchmarking, and optimization of load distribution across processing lines.

Equipment Manufacturing Plants and Automation Systems

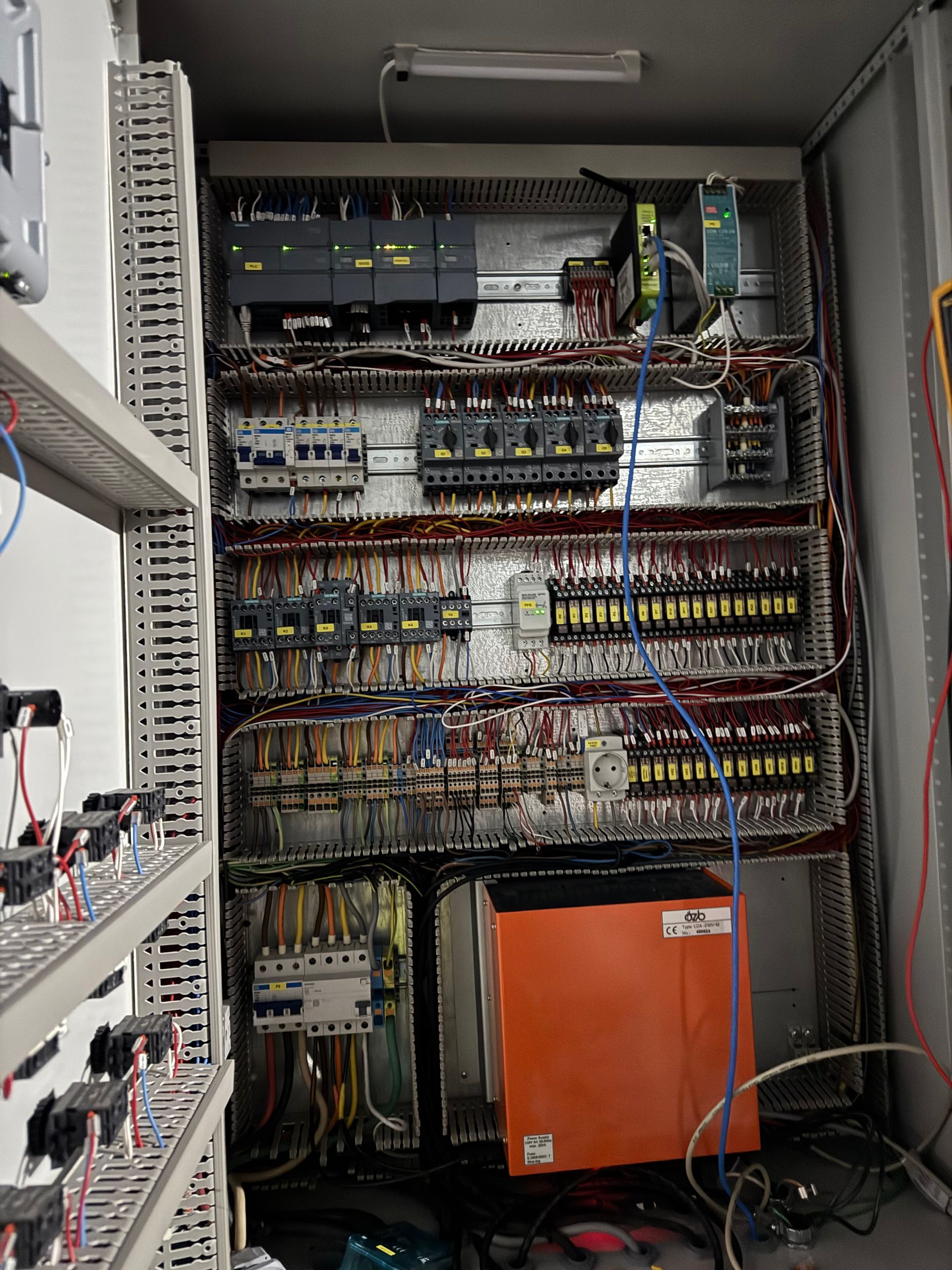

Manufacturing facilities rely heavily on automation, control panel design, PLC networks, and electrical systems that support fast-paced production environments. Frequency X Electric

delivers services that enhance equipment reliability and ensure automation platforms remain responsive and accurate. Manufacturing plants often involve a wide variety of machines, each requiring unique electrical interfaces, control logic, and instrumentation configurations.

Manufacturing System Requirements

These environments require electrical systems capable of supporting robotics, assembly-line machinery, process instrumentation, test stations, and material handling equipment. Frequency X Electric installs, configures, and maintains control panels, PLC systems, drive technologies, safety interlocks, and operator interfaces. Our team ensures each system communicates effectively with plant-wide automation networks, supporting streamlined production and consistent output

Thermosolar Facilities and High-Performance Electrical Infrastructure

Thermosolar installations, including facilities such as Gemasolar, rely on specialized electrical and control systems for heat collection, storage, and conversion processes. These environments involve advanced instrumentation,

automated tracking systems, and large-scale electrical distribution components. Frequency X Electric provides services tailored to the unique conditions of thermosolar operations.

Electrical Complexity in Thermosolar Environments

Systems must handle continuous exposure to extreme temperatures, rapid environmental changes, and precise energy conversion processes. Electrical evaluations focus on control accuracy, instrumentation reliability, drive coordination, and communication between system components. We support retrofits, ongoing maintenance, troubleshooting, and modernization to keep thermosolar facilities operating safely and efficiently.

EPM (Enterprise Project Management) Operations and Structured Facility Support

Enterprise Project Management environments require structured workflows, coordinated installations, and strict adherence to project timelines. Frequency X Electric

supports EPM-driven facilities and projects by providing predictable electrical installation, system assessment, troubleshooting, and equipment integration services that align with project expectations.

Structured Electrical Service for Project-Based Operations

Electrical systems in these environments must be installed or upgraded without disrupting active project phases. Frequency X Electric delivers coordinated scheduling, clear communication, and technical consistency across all project stages. Whether supporting industrial expansions, facility upgrades, or operational evaluations, our services ensure electrical systems meet the precise needs of project-driven operations.