Industrial Electrical Equipment Installation & Assessments in North Las Vegas

Frequency X Electric provides detailed industrial electrical equipment installation and assessment services for facilities throughout North Las Vegas and surrounding regions. Proper installation and ongoing evaluation of electrical equipment are essential for achieving reliable operation, extending system lifespan, and maintaining compliance with applicable standards. Our team works with both new and existing systems, ensuring each installation is electrically accurate, properly configured, and prepared for the demands of continuous or high-load operation.

Comprehensive Equipment Assessment and System Evaluation

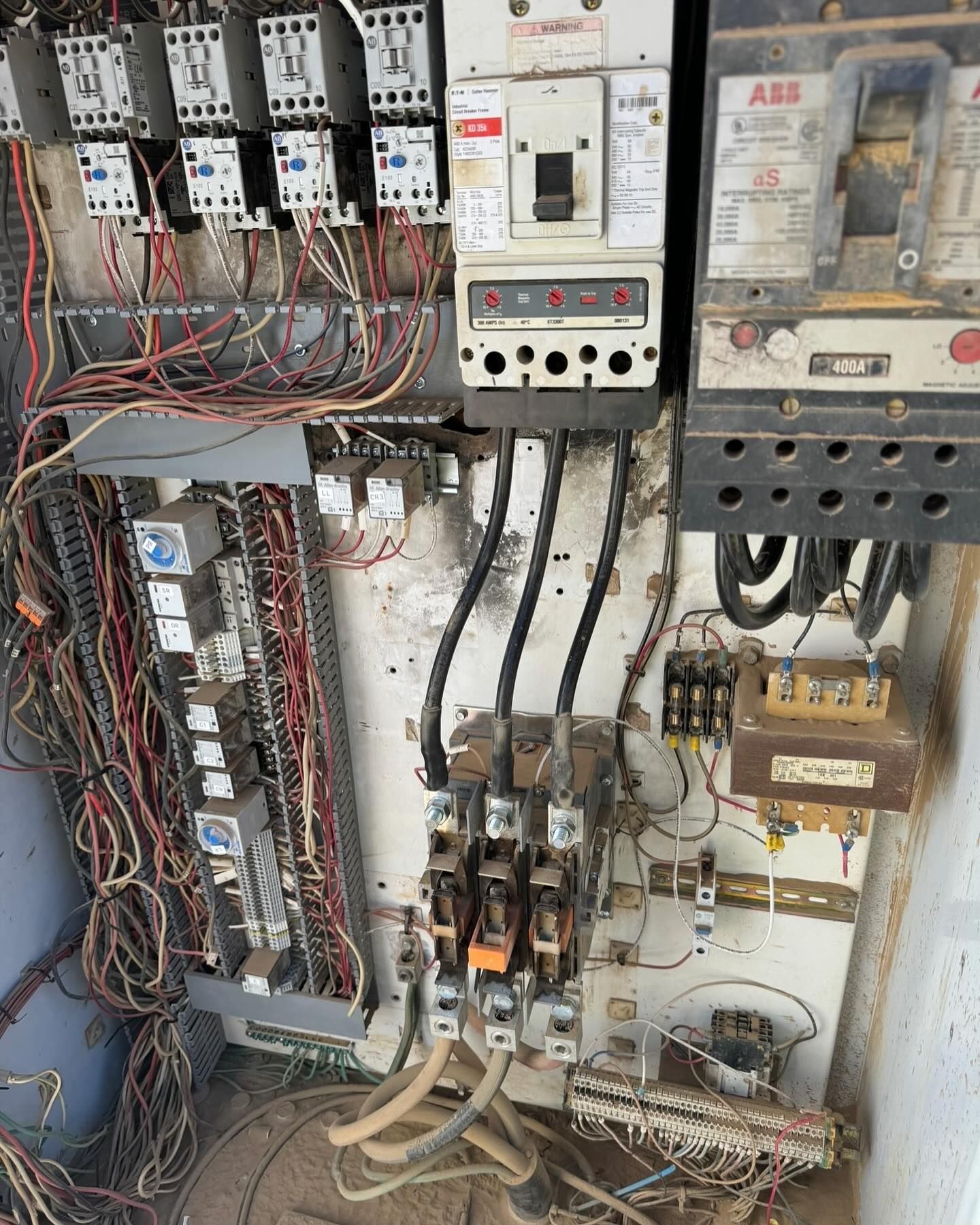

A thorough equipment assessment forms the foundation for understanding the condition, capability, and safety of an electrical system. Frequency X Electric conducts assessments that examine installation quality, operational performance, and overall reliability of industrial electrical equipment. These assessments are structured to identify risks, confirm proper functionality, and determine whether components meet industry expectations.

Evaluations include the condition of wiring, control systems, protective devices, electrical distribution equipment, and system communication. We assess system behavior under typical operational load and examine how it responds to

variable demand or environmental conditions. This approach allows facility managers and operators to address deficiencies, plan upgrades, or improve operational performance based on accurate technical insight.

Condition Assessments and Installation Quality Verification

Condition assessments focus on determining the health of existing electrical equipment and identifying factors that may affect long-term reliability. Frequency X Electric evaluates components such as electric motors, control panels, MCCs, VFDs, sensors, instrumentation, and distribution assemblies. Assessments determine whether equipment is functioning as intended, whether its condition aligns with expected service life, and whether installation practices meet

modern safety and performance standards.

Verification of Electrical Integrity

This segment of the assessment examines conductor sizing, torque accuracy, grounding continuity, and component condition. We verify that installation methods align with accepted electrical practices and that equipment is capable of sustaining its operational load.

Evaluation of Environmental and Operational Factors

Environmental elements such as vibration exposure, dust accumulation, moisture presence, and temperature fluctuations significantly influence equipment longevity. We assess how these factors interact with the electrical system and identify protective measures that can enhance stability.

Assessment of Component Performance and Electrical Load Behavior

We review thermal profiles, contact resistance, load balance, and system response under stress conditions. These findings help determine whether equipment requires servicing, calibration, or electrical component replacement.

Electrical System Evaluations and Performance Benchmarking

Electrical system evaluations explore the functional behavior of interconnected components, ensuring each part of the system communicates effectively and delivers predictable performance. Frequency X Electric benchmarks system

performance by studying voltage behavior, current demand, response time, and operational consistency across various operating conditions.

Electrical System Behavior Analysis

We observe how equipment responds to startup, shutdown, and sustained operation. This analysis identifies irregularities such as voltage drop, harmonic interference, unstable load distribution, or delayed response within control systems.

Comparative Performance Benchmarking

Benchmarking compares current equipment performance with industry standards and manufacturer specifications. It determines whether the system is performing within expected tolerances or whether modifications are required to improve efficiency or reliability.

System Compliance and Operational Readiness

We evaluate whether electrical systems meet regulatory requirements and readiness standards for continuous operation. This includes inspecting protective devices, control accuracy, and equipment integration

Upgrade Recommendations Based on Technical Assessment

After completing a detailed assessment, Frequency X Electric provides upgrade recommendations that reflect the current condition of the system and its future operational requirements. Industrial facilities often require modernized automation, improved control systems, or redesigned electrical infrastructure to meet production goals.

Upgrades may involve replacing outdated components, improving control panel design, integrating advanced instrumentation, modernizing PLC logic, or enhancing electrical distribution capacity. Each recommendation is technically driven and supported by assessment data, ensuring the upgrade path aligns with operational needs and long-term system planning.

Preventive and Predictive Maintenance Strategies for Long-Term Stability

A strong maintenance strategy is essential for sustaining equipment reliability after installation or assessment. Frequency X Electric provides preventive and predictive maintenance options tailored to industrial systems and commercial operations that depend on consistent electrical performance.

Preventive maintenance includes scheduled inspections, component verification, tightening of electrical connections, cleaning of control panels, functional testing, and visual review of equipment condition. Predictive maintenance adds a deeper level of analysis by examining operational trends, identifying signs of wear before they escalate, and tracking performance deviations over time. These strategies reduce unexpected downtime and ensure equipment remains aligned with performance benchmarks established during the assessment.

Maintenance planning also supports regulatory compliance by ensuring electrical systems receive proper documentation, testing intervals, and operational evaluations. This structured approach allows facilities to maintain safe, dependable electrical systems that respond effectively to current and future demands.